Why Cemplex Group is Upgrading Our Balcony Systems with Better Options

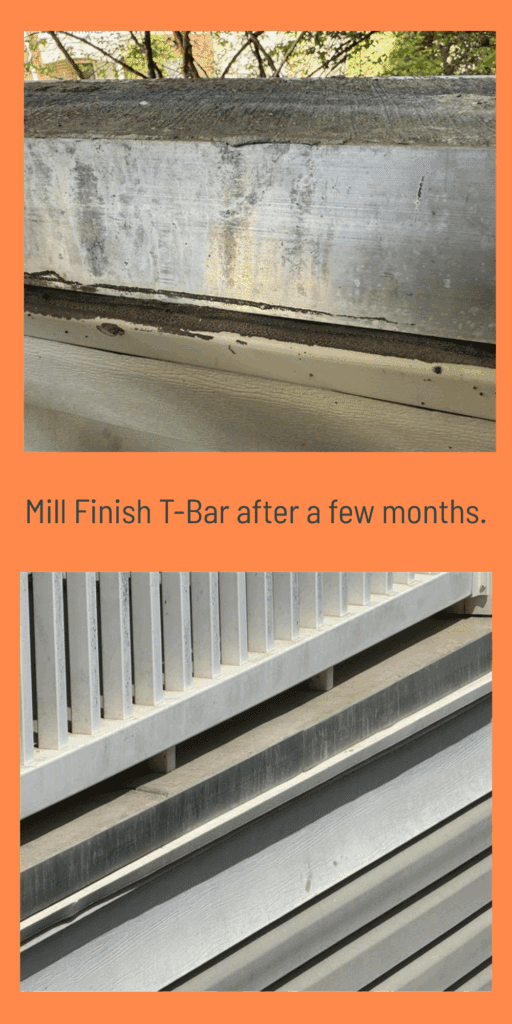

Mill Finish aluminum may have been the industry standard for years, but times, and expectations, have changed. At Cemplex Group, we know that long-term performance, durability, and visual consistency aren’t optional – they’re essential. That’s why we’re transitioning away from mill finish aluminum T-bar on all balcony systems.

T-bar is easily one of the most recognizable components of the balcony when standing on the ground below. Historically, it would deteriorate in appearance because of the highly alkaline water dripping across its face. By placing a drip edge at the top, this harmful water is shed away from the face of the T-bar leaving it bright and unblemished from the deleterious effects of the alkaline water.

Why the Change?

Mill finish aluminum is a reactive material. When exposed to the harsh elements of a construction site – rain, UV rays, and time – it corrodes, etches, and deteriorates. That’s unacceptable for a permanent, visible building component like a balcony drip edge.

T-Bar plays a critical dual role:

- It acts as a concrete form during the pour

- It becomes a lasting architectural feature once cured

So, we are raising the bar with two upgraded options: Primed or Anodized T-bar.

Primed T-Bar (Ready to Paint)

Designed for flexibility, this option allows job-specific customization to match architectural design intent.

BENEFITS:

- Factory-primed and ready for a topcoat

- Matches or contrasts with balcony trim and fascia

- Corrosion-resistant primer protects against alkalinity and moisture

- Superior paint adhesion for a long-lasting finish

Anodized T-Bar

This high-performance solution enhances the natural properties of aluminum for tough conditions.

BENEFITS:

- Easy to clean and maintain

- Oxide layer boosts corrosion resistance

- Scratch-resistant and durable under pressure

- UV-stable color retains its appearance

At Cemplex Group, we don’t meet industry standards, we set them. Our switch to primed and anodized options reflects our commitment to better systems, better finishes, and better results.

Our sales reps are already coordinating with clients to select the best-fit option for each project. If you have questions, we’re here to help.

Let’s build better – together.